Mounter

DEV2019-01-11T14:03:25+07:00Mounter

ARIATec provides the wafer mounter, semi-auto and table top manual to use for semiconductor industrial . The following is the products that we supply.

Contact us

Close

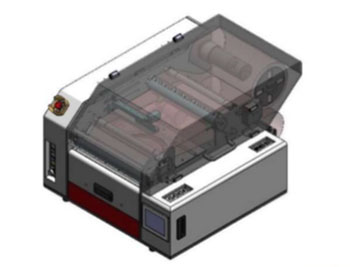

Takatori Wafer Mounter ATM-8200

Takatori Wafer Mounter ATM-8200

Features

- Full Automatic Wafer Mounter with Minimum foot print in the world.

- No damage due to lamination roller on ultra thin and no air bubbles because of adopting vacuum chamber.

- Tension control for all types of tapes is possible, so the optimal coating can be achieved to match post-processing requirements.

- Applicable for thin wafer.

Close

Takatori Wafer Mounter ATM-8100s

Takatori Wafer Mounter ATM-8100s

Features

- Mounting minimum 150-micron thick and max 5 mm-warped wafers.

- No damage due to lamination roller on ultra thin and no air bubbles because of adopting vacuum chamber.

- To process thin warped wafers, correcting the warpage inside vacuum chamber.

- Memorizing tape tension to meet wide range of tapes.

- (Option) To process 50 micron thick wafers, equipping the pattern recognition alignment and loader for coin stack jar, and integration with B/G machine, Etching machine, DM-800A and TEAM-200.

Close

Takatori Wafer Mounter ATM-8100x

Takatori Wafer Mounter ATM-8100x

Features

- Applicable precut tape, non-precut tape.(Non-precut tape is option)

- B/G tape removal function after mounting.

- Applicable ultra thin wafer.

- Wafer supply is available from open cassette, coinstack cassette.(Coinstack cassette is available as option)

Close

Takatori Wafer Mounter DTM-812X/W

Takatori Wafer Mounter DTM-812X/W

Features

- The footprint is smallest in the world despite the features of DAF lamination, mounting and BG tape removal.

- Standalone mode for ultra thin wafer.(Optional In-lining system with a grinder/polisher realizes the solution to the process of more ultra thin wafer)

- Vacuum chamber system is adopted for mounting wafers on dicing tape in order to avoid bubble generation between the tape and wafers as well as to minimize extra stress on the wafer surface. Either roll or precut type of dicing tape with DAF is applicable.

- DTM-812W is also line up with DDF laminating capability.

Close

Takatori Wafer Mounter ATM-12000DR

Takatori Wafer Mounter ATM-12000DR

Features

- Full automatic mounter for processing 12-inch (300 mm) wafers.

- Mounting a wafer, and then removing protective tape.

- No damage due to lamination roller on ultra thin and no air bubbles because of adopting vacuum chamber.

- Operations for replacing tape and supplying frames are centralized on the back of the machine.

- FOUP carrier. (option)

- In-line docking with B/G device, etching and polishing devices.

- Taking out wafers from a coin stacker. (option)

Close

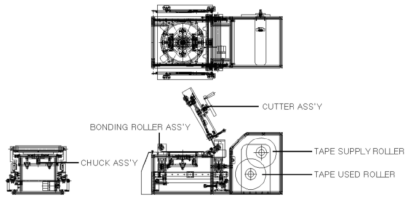

Takatori Wafer Mounter SAM-8

Takatori Wafer Mounter SAM-8

Features

- Contactless mounting table which holds wafer at 3mm edge part. (Vacuum for wafer holding is not necessary.)

- The adoption of a vacuum chamber system allows for reduced stress on the attachment rollers and the elimination of air bubbles, thereby preventing damage to the wafers and packages.

- Tension control for all types of tapes is possible, so the optimal coating can be achieved to match post-processing requirements.

- Automatic tape supply, tape coiling, wastage tape coiling, tape cutting.(UV tape applicable)

- Applicable for thin wafer.

Close

GSP Table Top Manual

GSP Table Top Manual

Specifications

- Blade life time: 10,000 sheets

- Wafer angle: 0′

- Tape consumption: About 30mm

- Mouting chuck

- Manual bond roller

- Manual tape feeding

- Manual residual tape cutter: V-cutter

- Application ring frame: 6″, 8″

- Application wafer: 6″, 8″

- Mount tape width:

- Application mount tape: Normal & UV tape

- Air supply pressure range: 5.0 Kgf/Cm2

- Air Supply: 10 x 1 tube

- Machine Weight: Approx. 80kg

- Size: About 450mm x 680mm x 410mm (L x W x H)

- Body color: Ivory

- Room temperature: 20~30

- Room humidity: 40~80%

Close

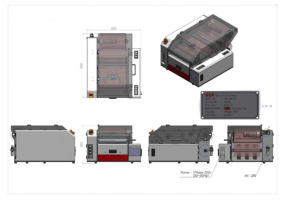

GSP Semi Auto Wafer Mounter

GSP Semi Auto Wafer Mounter

Key Features

- EASY CONVERSION BETWEEN 12”/10”/8”/6” AND 4” WAFER RING BY KIT

- PRE‐CUT TAPE

- CE CERTIFIED

Specifications

- VOLTAGE: 230 VAC, 50/60 HZ

- AIR: 0.49 MPA, 120 NL/MIN

- INPUT DEVICE: TOUCH SCREEN & BUTTONS

- INDIVIDUAL ADJUSTABLE FEED SPEED

- HEIGHT ADJUSTABLE FRAME BASE

- HEIGHT GAUGE FOR CHUCK TABLE HEIGHT ADJUSTMENT (WAFER

TABLE LEVELING JIG) - INTERNAL VENTURI VACUUM SYSTEM

- CONTACT SENSOR FOR TAPE DETECTION

- IONIZER (STANDARD BAR TYPE)

Close