TOSE Surfactant solution

TOSE Surfactant Solution

1

UPW SYSTEM

2

Proportion

3

Mix and Stir

4

Testing

5

Defoaming

6

Auto Filling

7

Packaging

8

Inspection

| Physical Propertyes | Specificaion |

| pH value | 6.0 – 7.5 |

| Specific gravity | 1.069 |

| Appearance/ Color | Slightly Cloudy |

| Solution in water | 100% soluble in water |

| Odor | Very mild to None) |

| Viscosity @ 25℃ | 0.91 Centipoise |

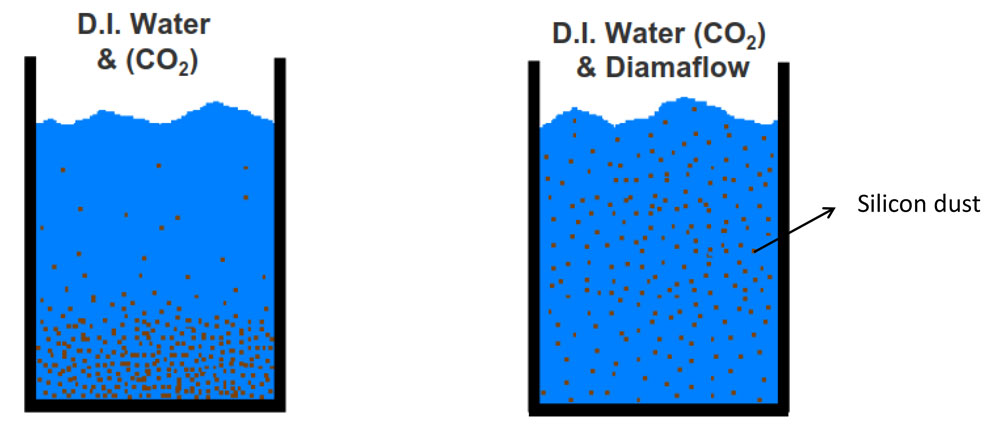

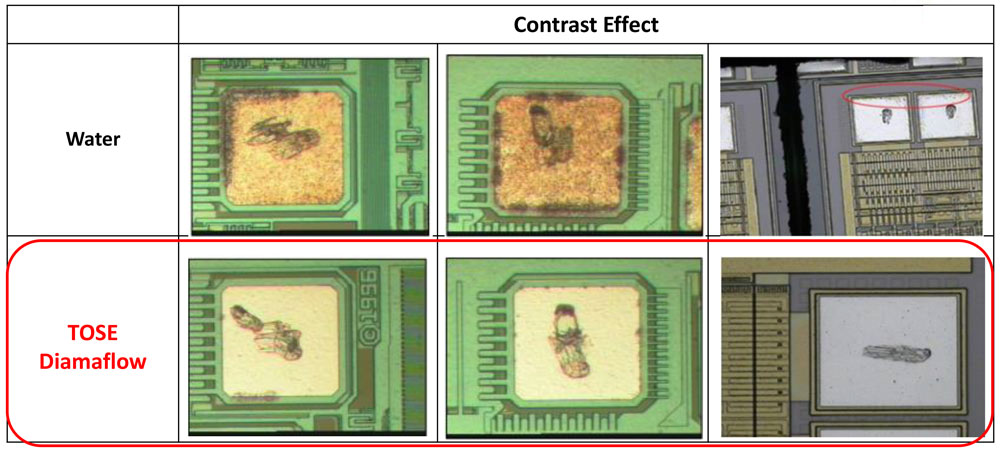

Only D.I. water is used, which has poor wettability. Water will not completely cover the surface of the wafer, and the surface tension reaches 72dynes/cm. Diamaflow is used to enhance the wettability, completely cover the surface of the wafer, and reduce the surface tension to 31dynes/cm.

Hydrophiilic(hydrophilic molecules) and Lipophilic(Lipophilic molecules) in Diamaflow will cover the silica dust, distribute it evenly in the cutting fluid with Diamaflow is wettability, and finally carry it off the wafer surface with water.

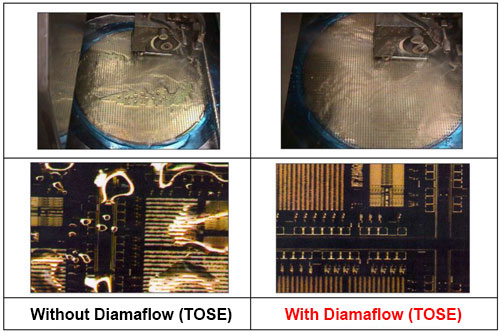

The material in Diamaflow can adsorb in Saw dust, which can prevent the cathode (welding spot) from contacting with the anode aluminum (Saw dust), thus preventing the formation of corrosive material (AL(OH3).