Micro-Spot Welding System

DEV2019-01-11T16:02:56+07:00Micro-Spot Welding System

ARIATec provides micro-spot welding system to use for semiconductor industrial . The following is the products that we supply.

Contact us

Vision-guided Micro-Spot Welding Robot with Single Module

Vision-guided Micro-Spot Welding Robot with Single Module

| Type | single module |

| Model | MLA-200.SW.001 |

| XYA motion distance | 260, 180, 20mm |

| Repetition positioning accuracy | ±0.015mm |

| Productivity | 1550pcs/hour(with 2 welding plate) |

| Typical applications | electro acoustic, micro motors |

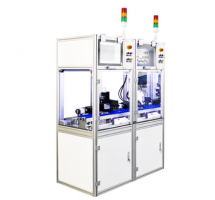

Vision-guided Micro-Spot Welding Robot with Double Module

Vision-guided Micro-Spot Welding Robot with Double Module

| Module type | double modules | |

| Model | MLA-200.SJ.001 | MLA-200.WD.001 |

| Module type | vision module | micro-spot welding module |

| XYZ motion distance | 80, 160, 20 mm | |

| Max load | 2.5kg | |

| Repetition positioning accuracy | ±0.015mm | |

| Axis NO. | 3 axis(X Y Z) | |

| Productivity | 2000pcs/hour (with 2 welding pad) | |

| Power | 600W | 900W |

| Wet. | 200kg | 200kg |

| Input voltage | 220V AC + 10% ~ 15%, 50Hz | |

| Typical application | micro motors | |

Vision-guided Micro-Spot Welding Robot, DW-100A

Vision-guided Micro-Spot Welding Robot, DW-100A

Introduction

DW series vision-guided micro-spot welding robot is one type of high precision welding machine, designed & developed for enameled wire welding, with the function of automatic positioning of welding point. DW-100A is one cost-effective welding robot, with the advantages of fast welding, highly precise positioning, & good consistency in welding.

Features

The DW-100A vision-guided micro-spot welding robot is specially designed for tiny copper wire and pad welding. This high quality welding device is highly cost effective equipment that is a desktop type spot welder for high precision production.

Performances

Automatic spot welding

Paint cleaning, spot welding

Adjustable welding parameters

Product-counting function

Parameter memory function

Real-time monitoring function during welding process

Pause, stop and alarm function

One-time operation, continuous operation

Specifications

| Model | DW-100A |

| Efficient welding area | 150mm ×150mm |

| Max motion speed | X/Y axis500mm/s, Z axis100mm/s |

| Repetition positioning accuracy | ±0.01mm |

| Positioning accuracy | ±0.05mm |

| Primary welding qualification rate | 98% |

| Productivity | 2.4 pcs/s(with 2 welding plates) |

| Applicable welding wire diameter range | 0.02~0.1mm |

| Overall size | 650 (W) × 700 (H) × 660 (D) (mm) |

| Wet. (kg) | about 105 |

| Voltage | 220VAC±10% 50Hz±2% |

| Power | 850W |

| Structure | desktop type |

| Driving type | Stepper motor + synchronous belt |

| Precision level | high precision |

| Operation | Man-machine type, automatic identification |

| Application fields | Tiny copper wire and welding plates in trumpet, buzzer, flat motor, etc. |

| Typical application | Phone speaker, mobile phone speaker; welding of copper wire, welding pad, etc. |

Equipment Requirements for Workpiece and Tooling

| welding pad | materials | Welding pad surface: copper or tin, basal plate: non-metal material; |

| shape | Welding pad edge: regular shape, clear edge; | |

| oversize | Basic dimensions of length, width or diameter should be 20 times of the welding wire; | |

| distance | Distance between each two adjacent welding plates should be more than0.5mm; | |

| Welding pad edge and non-metal material edge minimum distance should be more than0.5mm | ||

| Surface condition | Welding pad surface: smooth and in one level | |

| Welding pad surface should be free of glue, scratches, press, embossment, oxidation, etc. | ||

| Welding wire | Shape | The cross section of enameled wire or bare wire should be round shape; |

| Size | Diameter:0.02mm~0.1mm; (0.1~0.2mmshould be tested) | |

| Color | Wire color on tin welding pad: red, purple or other high color-difference(not for copper welding pad) |

Vision-guided Micro-Spot Welding Robot with Double Module

Vision-guided Micro-Spot Welding Robot with Double Module

| Module type | double modules | |

| Model | MLA-200.SJ.001 | MLA-200.WD.001 |

| Module type | vision module | micro-spot welding module |

| XYZ motion distance | 80, 160, 20 mm | |

| Max load | 2.5kg | |

| Repetition positioning accuracy | ±0.015mm | |

| Axis NO. | 3 axis(X Y Z) | |

| Productivity | 2000pcs/hour (with 2 welding pad) | |

| Power | 600W | 900W |

| Wet. | 200kg | 200kg |

| Input voltage | 220V AC + 10% ~ 15%, 50Hz | |

| Typical application | micro motors | |