Máy hàn điểm micro-spot

DEV2021-03-26T15:55:09+07:00MÁY HÀN ĐIỂM MICRO-SPOT

HNFCONS cung cấp các loại máy hàn điểm Micro-spot sử dụng trong các ứng dụng công nghiệp sản xuất điện tử tiêu dùng (camera modules, VCM, mobile phone frames, flat motors), sản xuất điện âm (magnetic buzzers, relays), hàn nóng, hàn tấm kim loại,… Dưới đây là một số sản phẩm tham khảo.

Liên hệ

Vision-guided Micro-Spot Welding Robot, DW-100A

Introduction

DW series vision-guided micro-spot welding robot is one type of high precision welding machine, designed & developed for enameled wire welding, with the function of automatic positioning of welding point. DW-100A is one cost-effective welding robot, with the advantages of fast welding, highly precise positioning, & good consistency in welding.

Features

The DW-100A vision-guided micro-spot welding robot is specially designed for tiny copper wire and pad welding. This high quality welding device is highly cost effective equipment that is a desktop type spot welder for high precision production.

Performances

- Automatic spot welding

- Paint cleaning, spot welding

- Adjustable welding parameters

- Product-counting function

- Parameter memory function

- Real-time monitoring function during welding process

- Pause, stop and alarm function

- One-time operation, continuous operation

Specifications

| Model | DW-100A |

| Efficient welding area | 150mm ×150mm |

| Max motion speed | X/Y axis500mm/s, Z axis100mm/s |

| Repetition positioning accuracy | ±0.01mm |

| Positioning accuracy | ±0.05mm |

| Primary welding qualification rate | 98% |

| Productivity | 2.4 pcs/s(with 2 welding plates) |

| Applicable welding wire diameter range | 0.02~0.1mm |

| Overall size | 650 (W) × 700 (H) × 660 (D) (mm) |

| Wet. (kg) | about 105 |

| Voltage | 220VAC±10% 50Hz±2% |

| Power | 850W |

| Structure | desktop type |

| Driving type | Stepper motor + synchronous belt |

| Precision level | high precision |

| Operation | Man-machine type, automatic identification |

| Application fields | Tiny copper wire and welding plates in trumpet, buzzer, flat motor, etc. |

| Typical application | Phone speaker, mobile phone speaker; welding of copper wire, welding pad, etc. |

Equipment Requirements for Workpiece and Tooling

| welding pad | materials | Welding pad surface: copper or tin, basal plate: non-metal material; |

| shape | Welding pad edge: regular shape, clear edge; | |

| oversize | Basic dimensions of length, width or diameter should be 20 times of the welding wire; | |

| distance | Distance between each two adjacent welding plates should be more than0.5mm; | |

| Welding pad edge and non-metal material edge minimum distance should be more than0.5mm | ||

| Surface condition | Welding pad surface: smooth and in one level | |

| Welding pad surface should be free of glue, scratches, press, embossment, oxidation, etc. | ||

| Welding wire | Shape | The cross section of enameled wire or bare wire should be round shape; |

| Size | Diameter:0.02mm~0.1mm; (0.1~0.2mmshould be tested) | |

| Color | Wire color on tin welding pad: red, purple or other high color-difference(not for copper welding pad) |

Vision-guided Micro-Spot Welding Robot, DW-200S

Introduction

DW series vision-guided micro-spot welding robot is one type of high precision welding machine, designed & developed for enameled wire welding, with the function of automatic positioning of welding point. DW-200S is one cost-effective welding robot, with the advantages of fast welding, highly precise positioning, & good consistency in welding.

Features

- The DW-200S vision-guided micro-spot welding robot is a desktop type spot welder, specially designed for the micro motor industry.

- Servo motor and screw rod platform for high efficiency and precision welding.

- CCD vision system, precise target-capture function.

- Transferring car for optional choice, desktop and cabinet type can be switched according to customer need.

- Real-time monitoring during welding, with the indicating functions of pause, emergency stop, alarm, etc.

Performances

- Automatic identification on welding spots, automatic paint peeling on enameled wires.

- Welding parameters can be adjusted, with the function of products count and parameter memory.

- Real-time monitoring.

- Pause, stop and alarm.

Specifications

| Model | DW-200S |

| Efficient welding area | 200mm ×200mm |

| Max motion speed | X/Y axis500mm/s, Z axis100mm/s |

| Repetition positioning accuracy | ±0.01mm |

| Positioning accuracy | ±0.02mm |

| Primary welding qualification rate | 98% |

| Productivity | 2.2 pc/second(two soldering plates) |

| Wire diameter range of welding workpiece | 0.02~0.1mm |

| Overall size | 700 (W) × 900 (H) × 740 (D) (mm) |

| Wet. (kg) | about 110kg |

| Power supply | 220VAC±10% 50Hz±2% |

| Power | 950W |

| Structure | desktop machine |

| Platform driving type | servo motor + screw rod |

| Accuracy level | high precision |

| Typical application | Linear motor , VCM, hot riveting and other precision parts welding |

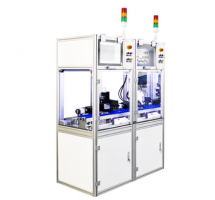

Vision-guided Micro-Spot Welding Robot with Single Module

Introduction

MLA single-module vision-guided spot welding robot is one production-line type of high precision welding machine; in addition to inheriting all the advantages of DW-200S, the welding machine also supports the module connection & expansion to build LA intelligent automated production line.

Features & Performance

The module is extendable and compatible with LA intelligent and automatic production lines. They are often used to produce micro motors and other electronics.

Specifications

| Type | single module |

| Model | MLA-200.SW.001 |

| XYA motion distance | 260, 180, 20mm |

| Repetition positioning accuracy | ±0.015mm |

| Productivity | 1550pcs/hour(with 2 welding plate) |

| Typical applications | electro acoustic, micro motors |

Vision-guided Micro-Spot Welding Robot with Double Module

Introduction

MLA double-module vision-guided spot welding robot is one production-line type of high precision welding machine; in addition to inheriting all the advantages of DW-200S, the welding machine also supports the module connection & expansion to build LA intelligent automated production line.

Features & Performance

- The vision module and welding module work independently for maximum production efficiency.

- Module extension function to set up LA intelligent and automatic production lines.

- CCD vision system: for real-time monitoring, product-counting, single or continuous welding. It can also pause, stop and set off an alarm in case of emergency.

- High-precision pressure sensor control of welding power, quality and consistency.

Specifications

| Module type | double modules | |

| Model | MLA-200.SJ.001 | MLA-200.WD.001 |

| Module type | vision module | micro-spot welding module |

| XYZ motion distance | 80, 160, 20 mm | |

| Max load | 2.5kg | |

| Repetition positioning accuracy | ±0.015mm | |

| Axis NO. | 3 axis(X Y Z) | |

| Productivity | 2000pcs/hour (with 2 welding pad) | |

| Power | 600W | 900W |

| Wet. | 200kg | 200kg |

| Input voltage | 220V AC + 10% ~ 15%, 50Hz | |

| Typical application | micro motors | |