Auto Vision Dispensing Machine

DEV2019-01-14T13:10:31+07:00Auto Vision Dispensing Machine

ARIATec provides auto vision dispensing machine to use for semiconductor industrial . The following is the products that we supply.

Contact us

3-Axis Automated Dispensing Robot

3-Axis Automated Dispensing Robot

DS-200B |

DS-300B |

DS-500B |

DS-200C |

Introduction

DS-B series 3-Axis automated dispensing robot is one practical type dispensing system, with gantry structure design, & can be qualified for conventional dispensing work; the system can be matched with Mingseal developed dispensing controller, non-contacted dispensing valves, high precision dispensing valves, & also other brands of dispensing controller. The system can read & work the program of AutoCAD file, or be operated by the teach pendant programming.

Features of the 3-axis automated dispensing robot

1. Point, stripe, arc, composite curves and different patterns of dispensing work

2. Aluminum profile structure (C), high rigidity for high precision

3. Keyboard programmed, stable, reliable and simple to operate with high automation

4. Various input and output I/O interface, with a wide range of functions

Performances

1. Stepper motor in the motion mechanism, to ensure the accuracy of robotic dispensing

2. Anti-drawing, anti-curing, automatic fillet over, smart array, etc.

3. Standard Modbus-RTU protocol, easily connected with other automated production line components

4. 5 channels of dispensing signal output to realize multi-channel time-sharing dispensing control

Typical Applications

- Mobile phone production: camera module, VCM precision dispensing

- Electro-acoustic: car horn, mobile phone speaker, microphone, receivers

- Consumer electronics: laptop case, battery box adhesive package dispensing

- Instrumentation: shell packaging

B type robot specifications

| Model | DS-200B | DS-300B | DS-500B |

| Working range X/Y/Z | 200mm /200mm/80mm | 300 mm /300 mm/100 mm | 500 mm /500 mm/100 mm |

| Platform loading | 5 kg | 5 kg | 5 kg |

| Repetition positioning accuracy | ±0.01 mm | ±0.01 mm | ±0.01 mm |

| Transmission type | Stepper + Synchronous belt | Stepper + Synchronous belt | Stepper + Synchronous belt |

| Task storage NO. | 120 pcs | 120 pcs | 120 pcs |

| I/O | 4 input / 4 output | 4 input / 4 output | 4 input / 4 output |

| Overall size(L W H) | 300mm × 300 mm × 410 mm | 420mm × 420mm ×450mm | 660mm × 640mm ×685mm |

| Wet. / kg | 17 kg | 32 kg | 81 kg |

| Programming type | Handheld programmer | Handheld programmer | Handheld programmer |

| Input volt. | 220V AC+10%~-15% 50Hz | 220V AC+10%~-15% 50Hz | 220V AC+10%~-15% 50Hz |

C type robot specifications

| Model | DS-200C |

| Working distance range X/Y/Z | 200 mm /200 mm/60 mm |

| Platform load | 3kg |

| Repetition positioning accuracy | ±0.01mm |

| Transmission type | Stepper + Synchronous belt(Z axis with brake) |

| Task storage NO. | 120 pcs |

| I/O | 12 input/ 12output |

| Overall size(L W H) | 440mm ×340mm × 440mm |

| Wet. | 22kg |

| Power | 150W |

| Programming type | Handheld programmer |

| Input volt. | 220V AC+10%~-15% 50Hz |

High Precision Dispensing Robot without Vision-guided Module

High Precision Dispensing Robot without Vision-guided Module

VS-C series high precision dispensing robot is one intelligent dispensing system, designed & developed for smart phone electronics, smart wearable electronics, LED, optical communication, etc. The system can be qualified for dispensing of electronics core filling, pin coating, FPC reinforcing, smart-phone frame & LCD edge gluing, NFC model assembling, flat motor assembling, smart-phone speaker & receiver assembling, etc.

Product Features

The high precision dispensing robot with out vision guided module have all of the existing features and advantages of VS-C series dispensing robot, but with additional features that make it a routine dispensing robot with high precision, high quality and high efficiency.

Solution Advantages

The high precision dispenser is new model based on the 3D motion platform of the servo wire rod. It can realize high precision positioning, fast coating efficiency, and high qualification rates of finished products.

Solution

VS-300C / VS-200C vision dispensing robot configurations: SS-300C platform + ZS-200.001 vision system + ZS-GY-100 dispensing process module + Mingseal conventional dispensing valves series (thimble type, single/double glue, etc.)

Specifications

See the VS-300C / VS-200C visual spraying robot related parameters

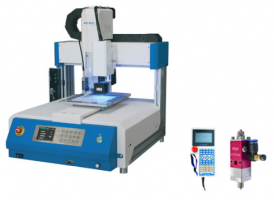

Vision-guided Dispensing Robot with High Precision Dispensing Valve

Vision-guided Dispensing Robot with High Precision Dispensing Valve

Introduction

VS-C series vision-guided dispensing robot is one intelligent visual identity robot system, designed & developed for smart phone electronics, smart wearable electronics, LED, optical communication, etc. The system can be qualified for dispensing of electronics core filling, pin coating, FPC reinforcing, CCM & VCM assembling, smart-phone frame & LCD edge gluing, fingerprint recognition core & module assembling, NFC model assembling, flat motor assembling, linear vibration motor assembling, smart-phone speaker & receiver assembling.

Product Features

The vision-guided dispensing robot with high precision dispensing valve features vision recognition software system is developed for the characteristics of CCM and VCM technology.

As for focus running and wire drawing when needles lens during manual dispensing, the piezoelectric injection valve can be chosen for non-contact dispensing operation.

As for the possible level deviation in lens focusing, and the height fluctuation caused by tooling, altimetry function can be used to eliminate the error.

Solution Advantages

Vision dispensing robot is new model based on the 3D motion platform of the servo wire rod. It can realize high precision positioning, fast coating efficiency, and high qualification rates of finished products.

Mingseal’s self-design visual software and operating system makes the fixture easy to install and debug, and the visual system easy to operate and understand.

Solution

VS-300C/200C vision dispensing robot configurations: SS-300C platform + ZS-200.001 vision system + ZS-GY-100 dispensing process module + PZT-JET5010 piezoelectric injection valve

| Model | VS-300C | VS-200C |

| structure | gantry type | gantry type |

| Axis NO. | 3 | 3 |

| Move distance (axis X/Y/Z) | 300/300/100 mm | 200/200/100 mm |

| Repeat positioning accuracy (axis X/Y/Z) | ±0.005mm | ±0.005mm |

| Resolution Ratio (axis X/Y/Z) | 0.002mm | 0.002mm |

| Loading plate load | 10KG | 10KG |

| Axis Z load | 5KG | 5KG |

| Power | 450W | 450W |

| Driving type | AC servo motor | AC servo motor |

| Transmission type | Lead screw | Lead screw |

| Lead distance | X/Y-20mm, Z-10mm | X/Y-20mm, Z-10mm |

| Oversize(L W H/mm) | 576×514×626 | 476×414×626 |

| Program type | based on PC | based on PC |

| Camera pixel | 1,300,000 pixels (higher pixels as optional) |

1,300,000 pixels (higher pixels as optional) |

| Light source | LED coaxial light(blue or red) | LED coaxial light(blue or red) |

| I/O | 12in / 12out | 12in / 12out |

| Wet. | 65kg | 57kg |

| Tasks memory | 120pcs | 120pcs |

| Input Voltage | 220V AC 50Hz | 220V AC 50Hz |

| Working environment | Temperature 0-40 ℃ Humidity 20-90% |

Temperature 0-40 ℃ Humidity 20-90% |

| Remarks: VS-200C cannot matched with laser altimeter module | ||