Flux cleaning solution

Flux Cleaning Solution

BIO Safe Cleaning Solution

HNFCONS provides the latest technology of flux cleaning solution in order to improve the wafer cutting precesses, package oxidation cleaning, mould cleaning,…

Advantages:

- Human Safe –NO organs decease / Cancer affect

- Environment Safe -100% BIO-degradable

- Products Safe –DO NOT attack on products’ surface

- Plant based surfactant / renewable source

- Low / Zero Volatile Organic Compounds (VOC)

- Safe to storage –Low flammability

BIO Clean Technology

All BIO clean are BIO-degradable. All derived from plants. It is environmental friendly, human safe and products safe. Nonreactive to products.

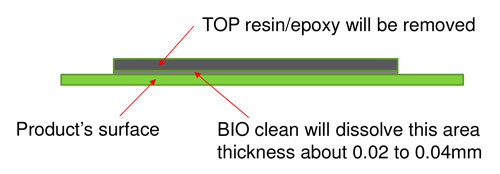

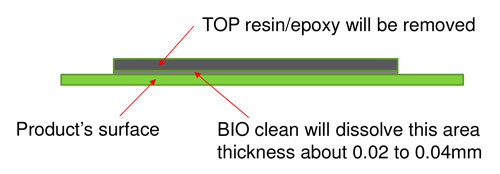

The cleaning process is dissolving and removing.

CLEAN = Dissolving + Removing

The Dissolve area thickness is about 0.02 to 0.04mm and remove the thicker resin/epoxy.

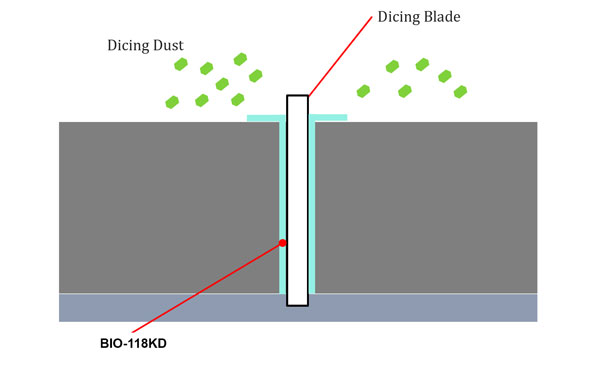

BIO-118KD –For Wafer Dicing

![]()

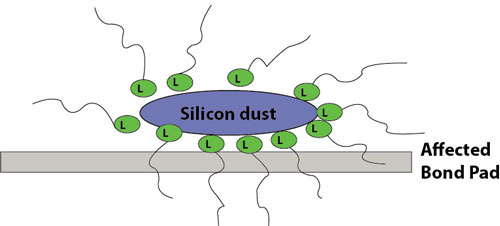

The new BIO-118KD penetrates into the gap between dicing Blade and Silicon Wafer.

-> DI water tension is reduced when mixed with BIO-118KD Bio clean.

Effects:

- It reacts as cooling effect and reduce the heat generate during dicing

- It helps to reduce the chipping at top and bottom side

- Can improve the life-span of dicing blade

- On top of the silicon wafer surface, the additive will help to flush away the dicing dust and prevents pad contamination

- It provides corrosion free environment

BIO-118KD –For Diamond / Ceramic Cutting

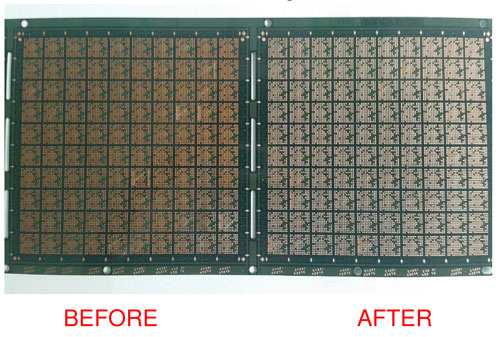

BIO Clean BIO-52KD –Package Oxidation Cleaning

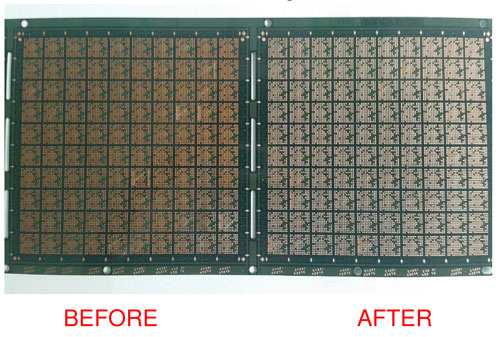

- BIO-52KD is able to clean the package oxidation within 35 mins manually.

- It should be able to clean by ultrasonic too. A proper cleaning solution

- This BIO-52KD is BIO clean has no harm to package with better cleaning condition. It is BIO-degradable.

- This a safe cleaning solution for industrial.

- + WHY BIO CLEAN

-

Advantages:

- Human Safe –NO organs decease / Cancer affect

- Environment Safe -100% BIO-degradable

- Products Safe –DO NOT attack on products’ surface

- Plant based surfactant / renewable source

- Low / Zero Volatile Organic Compounds (VOC)

- Safe to storage –Low flammability

- + TECHNOLOGY

-

BIO Clean Technology

All BIO clean are BIO-degradable. All derived from plants. It is environmental friendly, human safe and products safe. Nonreactive to products.

The cleaning process is dissolving and removing.

CLEAN = Dissolving + Removing

The Dissolve area thickness is about 0.02 to 0.04mm and remove the thicker resin/epoxy.

- + APPLICATION

-

BIO-118KD –For Wafer Dicing

The new BIO-118KD penetrates into the gap between dicing Blade and Silicon Wafer.

-> DI water tension is reduced when mixed with BIO-118KD Bio clean.

Effects:

- It reacts as cooling effect and reduce the heat generate during dicing

- It helps to reduce the chipping at top and bottom side

- Can improve the life-span of dicing blade

- On top of the silicon wafer surface, the additive will help to flush away the dicing dust and prevents pad contamination

- It provides corrosion free environment

BIO-118KD –For Diamond / Ceramic Cutting

BIO Clean BIO-52KD –Package Oxidation Cleaning

- BIO-52KD is able to clean the package oxidation within 35 mins manually.

- It should be able to clean by ultrasonic too. A proper cleaning solution

- This BIO-52KD is BIO clean has no harm to package with better cleaning condition. It is BIO-degradable.

- This a safe cleaning solution for industrial.

- + DOCUMENT

-